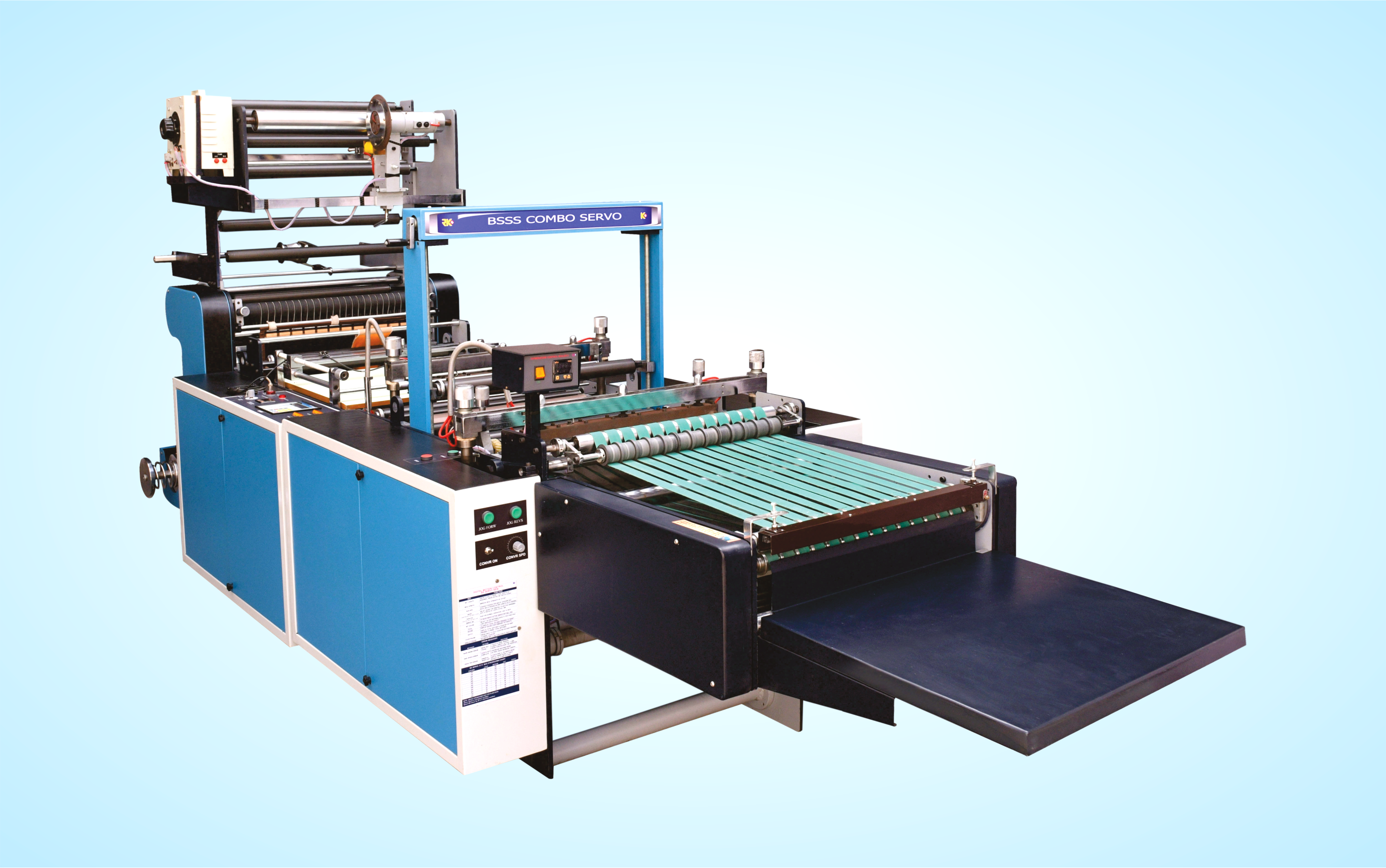

Courier Bag-Making Machine

All Products > Courier Bag Making Machine

Courier Bag-Making Machine

A multi-function, very easy-to-operate automatic

courier bag-making machine can also be used

to run BOPP & other side seal jobs.

- Specifications

- Highlights

- Options

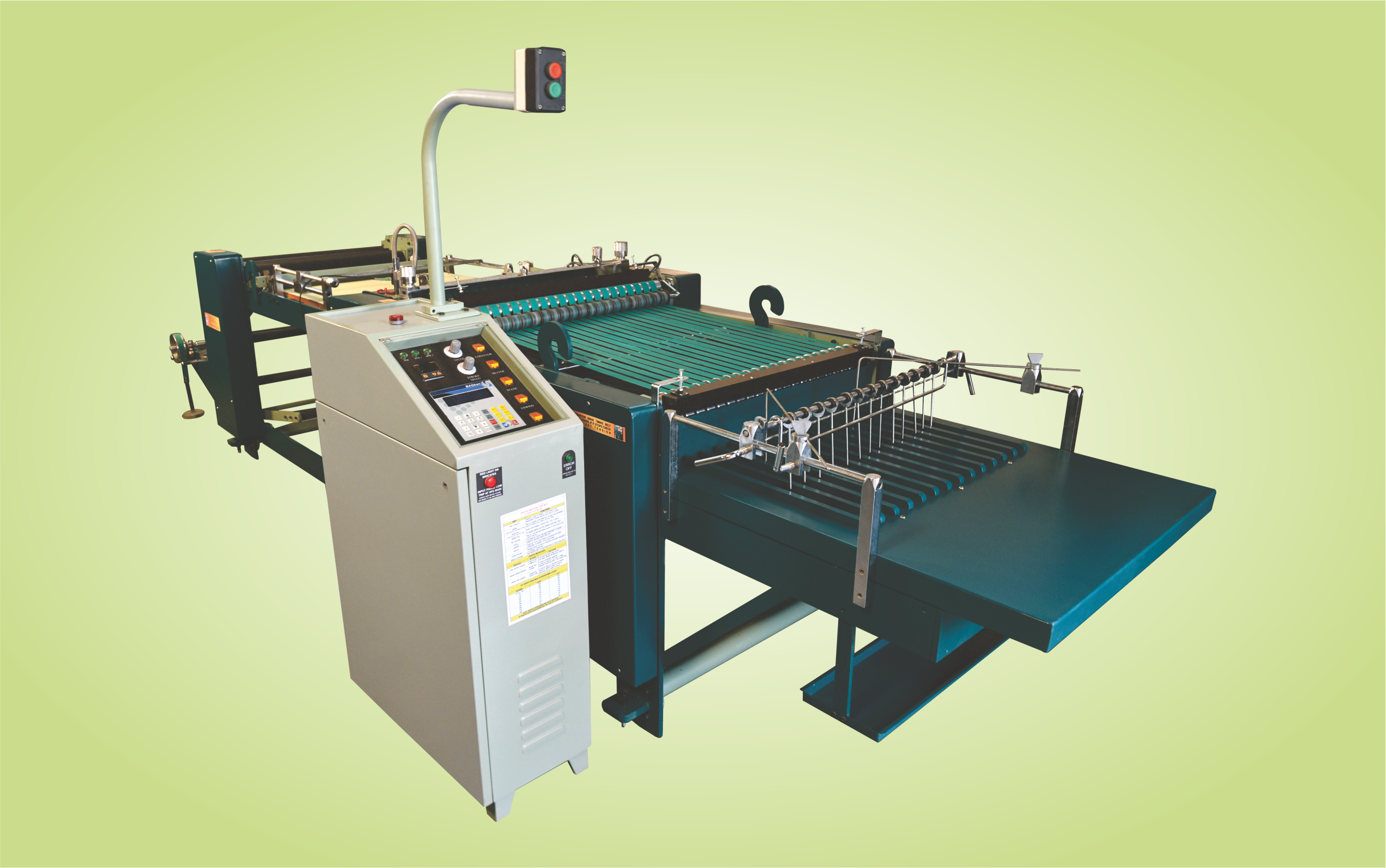

| MODEL | CB700 |

|---|---|

| MAXIMUM CUT WIDTH | 600 mm |

| MAXIMUM CUT LENGTH | 600 mm |

| MAXIMUM SHEET ROLL DIAMETER | 700 mm |

| MAX POD ROLL DIAMETER | 500 mm |

| MAX SPEED W/PSS & POD | 210 Stroke/min 100 Stroke/min |

| TOTAL CONNECTED LOAD | 11.5 KW |

| DIMENSION | W-1650 X H-2200 X L-6150 |

| MOTOR AC CONVEYOR MAIN WITH GEARBOX UNWIND SERVO | 0.75 HP 1 HP 2 HP 1 KW |

| HOT MELT GLUE | VALCO MELTON |

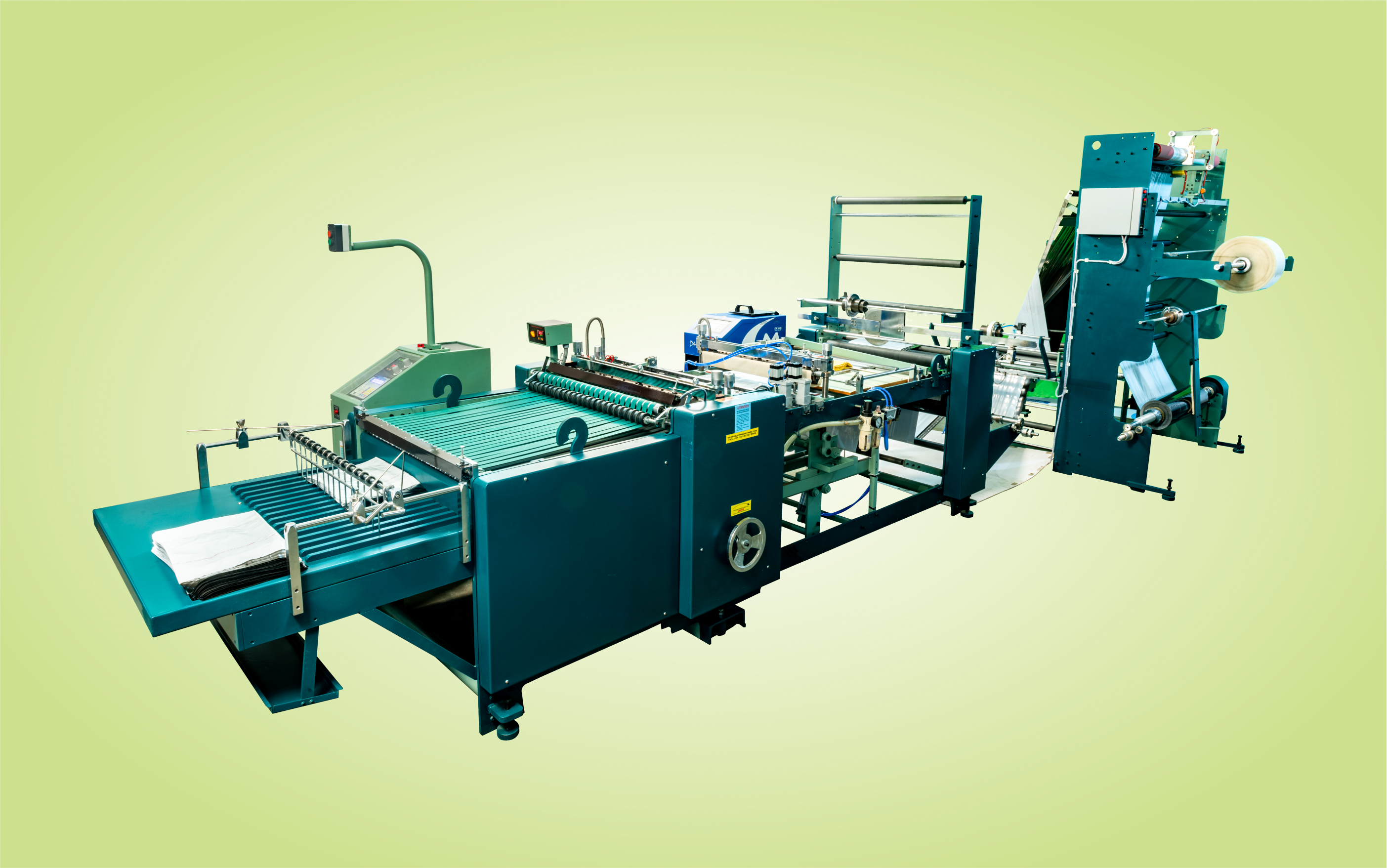

- A complete automatic microprocessor controlled setup

to make printed/plain courier bag in a single process. - Hot melt glue auto start/stop with release liner sensor.

- Auto POD sealer contact / release.

- No expert operator required.

- Unwind speed synchronization with stroke & size.

- Minimum maintenance

- 2nd glue line.

- Centre perforation.

- 2nd POD sealer for over-lopping POD type of courier.

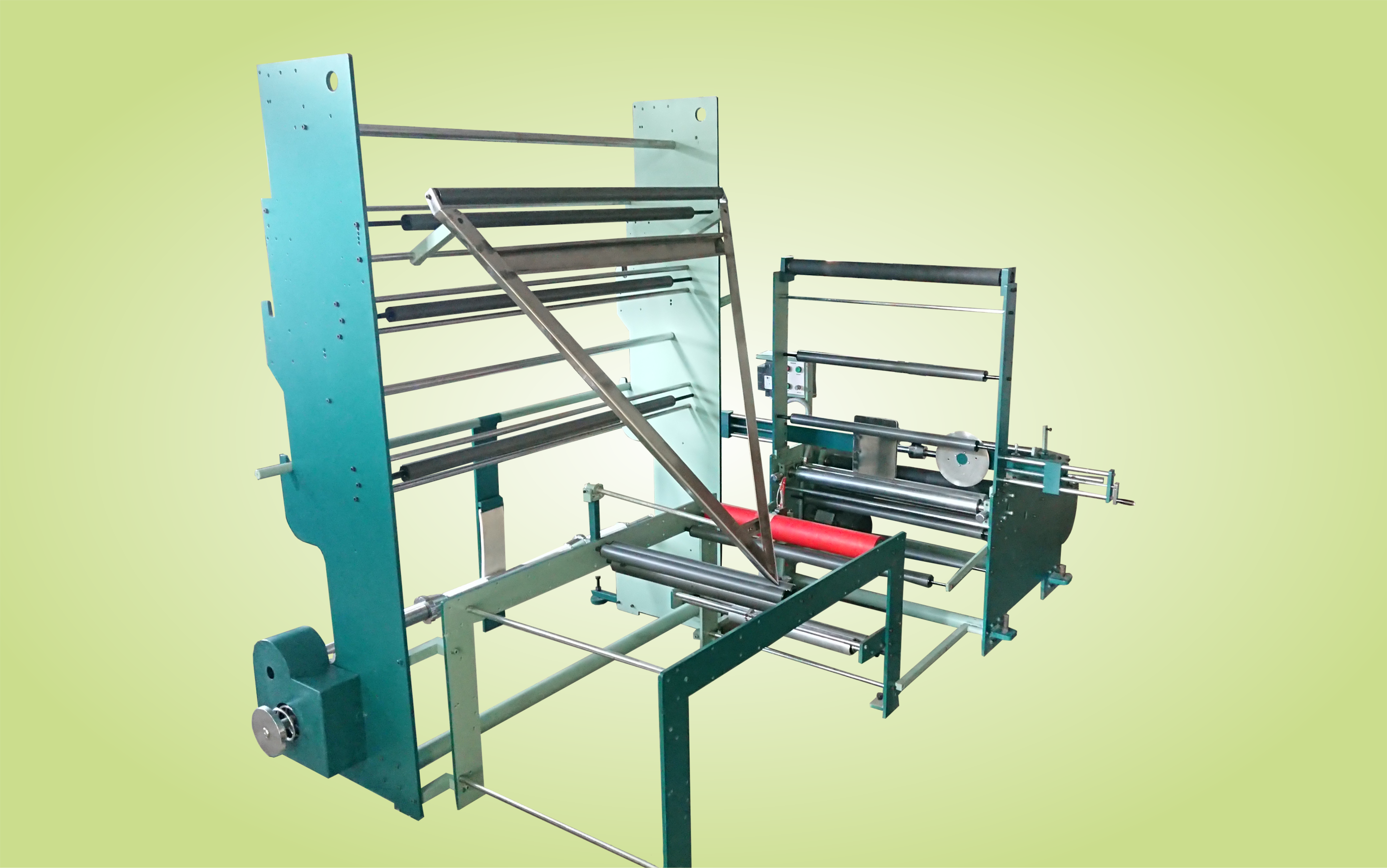

- Flap opening for converting courier bags from tube

form (POD stuck with BOPP self adhesive tape) - Pneumatic Sealing station for extra seal line

(temper proof sealing) - Intermittent gluing for printed bags.